That plaintive cry made the rounds of management conferences for years as executives charged with making the enterprise more efficient or tightening its supply chain or enhancing its value or building its brand equity struggled with how to achieve their amorphous but urgent goals.

The convergence of better data, mobile computing and improved organizational design may now be delivering solutions to address those needs.

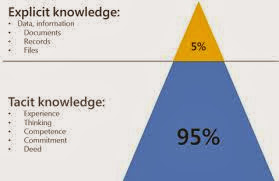

The focus has much to do with the design and application of knowledge. But it also has to do with changing the psychology of management processes. The 'Daddy-Knows-Best' approach to IT, in which a small priesthood of annointed experts does the thinking for the rest of the institution is being supplanted by a more inclusive approach that recognizes the wisdom accumulated through years of experience. Sometimes called tacit knowledge, this method actively incorporates the thinking of those who do the actual work.

It is, in its way, revolutionary, because it acknowledges the intelligence of - in the UPS case - the driver while also implicitly communicating that the organization trusts the employee with sharing the enterprise's best interests. And this in a company where all of the drivers are members of the Teamsters Union.

The larger implication is that for globally competitive institutions, no information can be ignored or wasted, whatever the source. JL

Mohana Ravindranath reports in the Washington Post:

UPS unveils software that would infuse a computer-generated route with driver feedback, among other sources.

Almost daily for the past seven years, United Parcel Service driver Ryan Brown has followed the same routine: He gets to the freight center about 8 a.m., inspects his truck for safety hazards and checks his delivery list for the day, mentally planning a route.

In a day, Brown might drive more than 100 miles in and around Dothan, Ala., making about that many stops for deliveries or pickups. The drivers of UPS’s more than 60,000 trucks nationwide are equipped with a hand-held computer that automatically suggests a route, based on delivery and pickup locations for the day

But after years of driving in the same town, Brown knows some things the computer doesn’t: best delivery times, which streets are hard to navigate and where to park so he can make several deliveries at once. He often strays from the computer’s suggested path and takes his own route, which he calls “going off-trace.”

“I try to stay as efficient as possible,” Brown said.

He knows, for instance, certain businesses open later than others, so he moves those deliveries down in his mental list. If he doesn’t consider such factors, he won’t be able to deliver all packages by their requested time, he said.

UPS unveils software that would infuse a computer-generated route with driver feedback, among other sources.Called on-road integrated optimization and navigation (ORION), the software accounts for geographic obstacles, customer requests and data about past deliveries before suggesting a route. Just as they do today, drivers would download the route to their hand-held computers before leaving for deliveries.

UPS has been installing ORION since October, and it will probably get to Brown’s truck in Dothan by the beginning of next year. It’s been an expensive, multiyear project, said UPS’s technology vice president, Juan Perez. Each year, UPS invests about $1 billion in technology, including ORION, whose software the company has been working on since 2003. For several years, the development team has been gathering data about driving patterns by installing sensors in some trucks.

Ultimately, the software could save UPS millions of gallons of gas each year and about $50 million in the United States in fuel costs, Perez said. It’s one of many adjustments UPS has made to save time and fuel. Since 2004, the company has discouraged drivers from taking left-turns on their routes, saving millions of gallons of gas. And in the past year, UPS has been implementing keyless trucks, so drivers don’t have to waste time searching their pockets for keys.

Such changes are about more than efficiency, Perez said, remarking, “We believe these technologies are going to put us in a position to provide better services to customers.”

Two years ago, the company launched UPS “My Choice”, which lets customers control the timing and location of a delivery — requests from My Choice are now funneled into ORION.

The software is expected to go through several releases, Perez said. The technology team is developing ORION’s ability to adjust a route depending on weather, traffic or a driver’s preferences. Currently ORION doesn’t update after a driver leaves the UPS center.

It’s a challenge to make sure that ORION uses accurate data to create routes, he said. The development team may have to review maps with dispatchers or drivers to make sure the information reflects a town’s geography, for instance.

“It’s a perfect example of garbage in and garbage out,” he said, referring to the fact that computers receiving bad data are likely to spit out the same. “We spend a significant amount of time in the early stages of the implementation process making sure we have good, clean data.”

Until it can make adjustments in real time, ORION can only complement, and not replace, the driver’s judgment, said UPS’s director of process management, Jack Levis, who has been working on ORION since its inception.

“We do want drivers to override ORION if it doesn’t make sense,” he said.

0 comments:

Post a Comment